About the Recycling Process

View all-

![]()

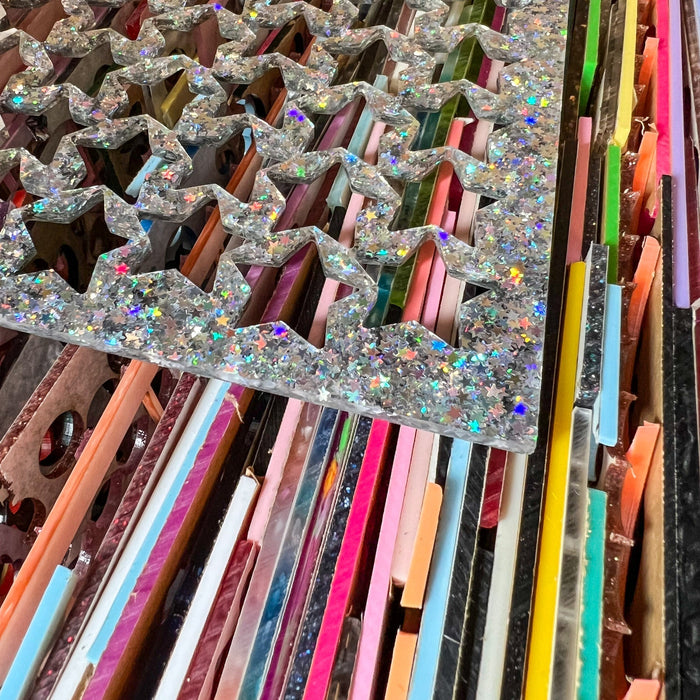

1. The Acrylic Waste Problem

Acrylic offcuts and waste scrap is an inevitable bi-product of the laser cutting process. Jewellery makers laser-cut acrylic shapes from flat sheets of acrylic plastic, and the surrounding acrylic is left behind.

As a class 7 plastic, acrylic is not easy to recycle. This is especially true if it contains additional additives like glitter or specialty pigments.Huge amounts of acrylic scrap becomes destined for landfill. -

![]()

2. There's a better solution than Landfill!

Plastic is an immensely useful material, and so precious because of the resources it consumes during its manufacture.

Just because acrylic offcuts can exist in awkward shapes and sizes, it doesn't mean they are destined to be discarded. Although challenging, acrylic scraps can be re-combined through a fusion process into beautiful new sheets ready for laser cutting into long lasting and totally unique recycled products. -

![Scrap acrylic sheets showing a white paper masking film being peeled off.]()

3. Material Preparation

Acrylic scrap comes in all shapes and sizes. Oh Pluto has sourced acrylic waste in-house, from larger laser cutting companies based in Australia, as well as from smaller local jewellery makers.

It often comes covered in a protective film that must also be removed. Intact sheets can be pressed as-is, or broken down by hand into smaller pieces before being mixed with other scraps, ready for the melt pressing process.

-

![A melt pressed recycled acrylic sheet showing a randomised assortment of green, pink and caramel coloured acrylic scraps pressed within.]()

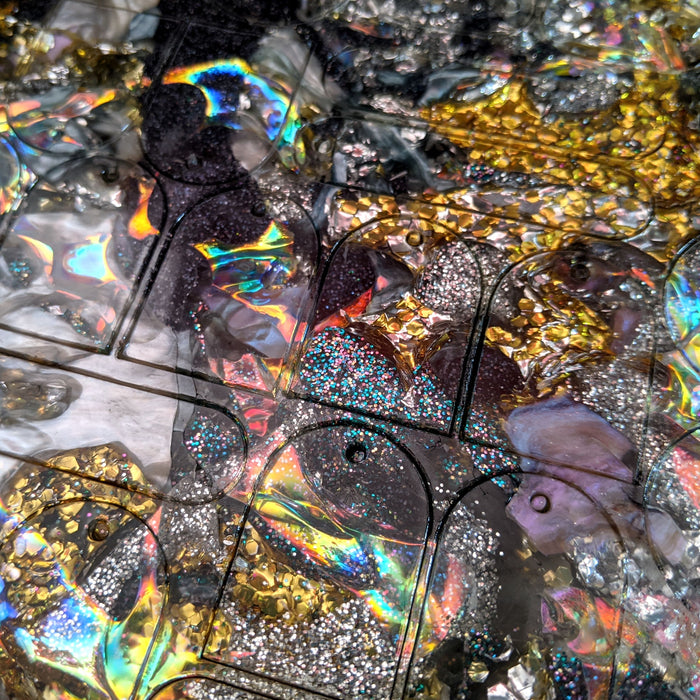

4. Pressure + Heat = New Life

Through much experimentation, an in-house process has been developed to melt press acrylic scraps together into new sheets. This requires high heat and a LOT of pressure.

Each resultant sheet has it's own amazing personality, is beautifully unique and one-of-a-kind.

-

![Recycled acrylic sheet with earring cutouts]()

5. Cutting into the New

Through careful planning, stunning shapes can be cut from the new recycled sheets. Due to the nature of the process, each sheet and each shape will be variable and unique.

The small batch nature of the process means that only ~5-20 jewellery pieces may come from a particular sheet, making them very limited edition!

-

![Colourful arch shaped earrings held in a hand with a blue background and the leftovers of a recycled acrylic sheet.]()

6. The Final Steps

Once cut up, all pieces are checked for defects, tidied up around the edges, washed and polished. They are then assembled into earrings, necklaces or brooches, and individually photographed. Phew!

Browse Available Recycled Products

View all-

Recycled Acrylic Earrings 'Sunset Reef' Collection. Pair 4

$40.00 AUDUnit price /Unavailable -

Recycled Acrylic Earrings 'Dusky Petals' Collection. Pair 5

$40.00 AUDUnit price /Unavailable -

Recycled Acrylic Earrings 'Sunset Reef' Collection. Pair 1

$40.00 AUDUnit price /Unavailable -

Recycled Acrylic Earrings 'Sunset Reef' Collection. Pair 3

$40.00 AUDUnit price /Unavailable -

Recycled Acrylic Earrings 'Sunset Reef' Collection. Pair 10

$40.00 AUDUnit price /Unavailable -

Recycled Acrylic Earrings 'Sunset Reef' Collection. Pair 11

$40.00 AUDUnit price /Unavailable -

Recycled Acrylic Earrings 'Sunset Reef' Collection. Pair 12

$40.00 AUDUnit price /Unavailable -

Recycled Acrylic Earrings 'Sunset Reef' Collection. Pair 14

$25.00 AUDUnit price /Unavailable